Xenon Test Chamber

The xenon test chamber uses a xenon arc lamp as a light source. It used for the study of weathering and accelerated aging testing by closely emulating true environmental conditions.

Controlled product degradation study (weathering), using varying light spectrum, temperature and moisture. Used to evaluate the weather resistance of the test material or samples.

The weathering test is an important way to optimize the composition of your product in the process of scientific research and production. It is also an important part of product quality inspection. Industries such as coatings, plastic, aluminum-plastic plate and automobile safety glass are all required to do this kind of weather ability test.

The test samples placed at a certain temperature, light and moisture at alternating cycles using a set program can replicate months or years of damage caused by outdoor weathering in a matter of days or weeks.

Some commonly methods our chambers can be used for are the following:

- ASTM G155: Standard Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials.

- ASTM 04459: Standard Practice for Xenon-Arc exposure of plastics intended for indoor applications.

- ISO 4892-1 Plastics – Methods of exposure to laboratory light sources.

- ISO 16474-2 Paints and varnishes – Methods of exposure to laboratory light sources – Part 2

Features

- Cost-effective.

- Wide spectral range.

- Offered in both flatbed and circular drum configurations.

- SOLAR EYE TM, automatic monitoring and control of internal conditions.

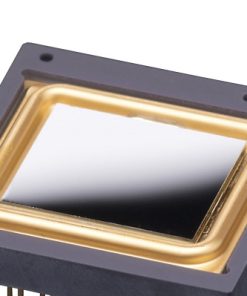

- S1 high-purity quartz transparent film, gold-plated silicon corrosion-resistant reflector, high temperature linear photosensitive components to ensure that the measurement accuracy is not affected by changes in high and low temperatures.

Advantages

It provides a more realistic study of degradation than conventional UV chamber testing. Wider spectral range and optional ultra-wide spectrum yields more real-world results.

The main factors that cause the aging of materials is sunlight and moisture. The Xenon Test Chamber can simulate the degradation caused by sunlight, rain and dew. The Xenon Test Chamber uses the xenon lamp to simulate the damage of sunlight, and uses condensed moisture simulates the rain and dew.

| Model | QT-WTH-80 | QT-WTH -175 | QT-WTH -500 |

| Test Volume | 80L | 175L | 500L |

| Test Chamber Type | Flat Bed | Flat Bed | Revolving Drum |

| Inter Dimensions | 500 × 400 × 400mm | 700 × 500 × 500mm | 800 × 800 × 800mm |

| Outer Dimensions | 700 × 1100 × 1950mm | 900 × 1150 × 1950mm | 1350 × 1350 × 1950mm |

| Cooling System | Air Cooling | Water Cooling | |

| Temperature Range | RT+10°C to 65°C | RT+10°C to 85°C | |

| Humidity Range (brightness) | 20% to 70%RH | 20% to 78%RH | |

| Humidity Range (darkness) | 20% to 95%RH | 20% to 98%RH | |

| Spraying Period | 1 to 240 minutes | Interval (cut-off) | |

| Spectral Wavelength | Standard: 290 to 800nm upgradable to 200 to 3000nm | ||

| Power Consumption | 9KW, (Temperature in +25.C, Without Sample Load) | ||

Reviews

There are no reviews yet.